As a critical step in chip manufacturing, wet cleaning accounts for approximately 30% of the entire process. Today, in conjunction with a paper, let’s discuss how to fine-tune oxide films with SC1 cleaning—balancing contaminant removal while maintaining uniform thickness! 👇

Key Finding: Through a five-factor experiment (rotation speed, flow rate, temperature, composition ratio, time), the etch rate and uniformity when SC1 cleans thermal silicon oxide films can be precisely controlled.

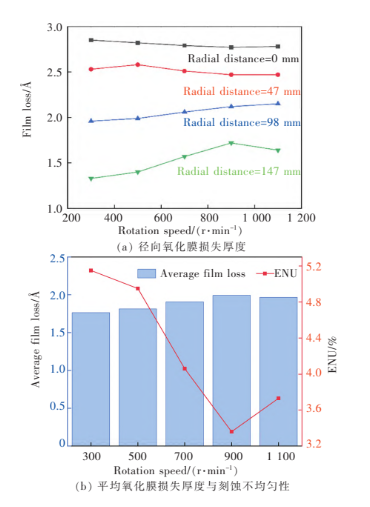

Rotation Speed Optimization: At 500–700 rpm, liquid film coverage is most uniform, avoiding issues with high-speed splashing. Excessively low rotation speeds (e.g., 300 rpm) lead to excessive etching at the center, forming "pits."

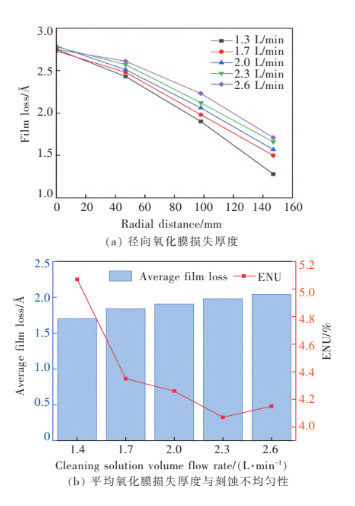

Flow Rate Control: A volumetric flow rate of 1.7–2.3 L/min balances uniformity and impact risk (avoiding pattern damage from the "hydraulic jump phenomenon").

Temperature Sensitivity: The etch rate grows exponentially with temperature! At 60°C, the thickness loss reaches 1.88 Å, but at 25°C, there is nearly zero etching—high temperatures enhance contaminant removal, while low temperatures preserve precision.

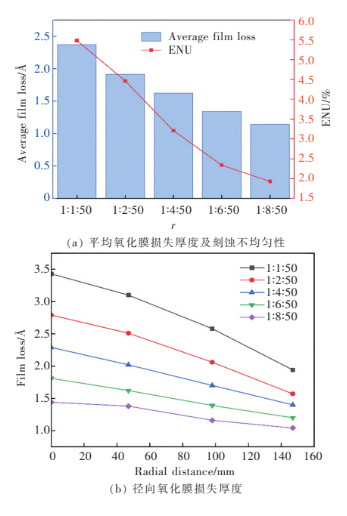

Composition Ratio Magic: The higher the H₂O₂ proportion, the more linearly the etch rate decreases (e.g., a 1:8:50 ratio achieves only 1.93% non-uniformity), making it suitable for precision applications like gate oxide layers.

Time Effect: The first 180 seconds of cleaning constitute a rate ramp-up period, after which it stabilizes; parameters must be matched to avoid excessive loss.

Professional Insights:

For oxide layers with relaxed thickness requirements, high temperature + low H₂O₂ ratio can be used to enhance contaminant removal;

For processes with stringent uniformity demands, medium temperature + high H₂O₂ ratio (e.g., 1:4:50) is recommended to strike a balance between efficiency and flatness.

参考文献为:《IC单片湿法清洗中SC1清洗工艺对热氧化硅膜刻蚀速率及表面均匀性的影响》